Reliability Data Collection and Analysis Resources

Training

Gain Skills in Stress-Strength Analysis, Reliability Demonstration Test Methods, Design of Experiments, and More

Sign up today for Reliability 201: Quantitative Reliability Analysis or Weibull Analysis!

Register today for hands-on training to be hosted Sept. 9-11, 2025 in Albuquerque, NM to introduce you or your employee(s) to reliability engineering in Reliability 201: Quantitative Reliability Analysis or train you how to use one of the most widely used and effective reliability analysis methods in the Weibull Analysis course.

Design engineers, new reliability engineers, product/program managers, and anyone interested to gain a basic understanding of reliability engineering or advance your knowledge with specific skills and techniques, this training is for you.

Course Dates

Tuesday, Sept. 9 – Thursday, Sept. 11, 2025.

Course Location

Drury Inn & Suites Albuquerque North

4310 The 25 Way Northeast

Albuquerque, NM 87109

Training Cost

The cost per course is $2,495. Group discounts are available!

Datasets

Nonelectronic Parts Reliability Data – NPRD-2023

Nonelectronic Parts Reliability Data – NPRD-2023

The 2023 Edition of the Nonelectronic Parts Reliability Data publication (NPRD-2023) is available through ROADS! presents field failure rate data on a wide variety of mechanical and electromechanical parts and assemblies. The parts cover ground, airborne and naval environments. NPRD-2023 adds 300,000 new failure rate records and 13,000 new components compared to its predecessor.

Electronic Parts Reliability Data – EPRD-2024

Electronic Parts Reliability Data – EPRD-2024

Harness the power of electronic parts component data for efficient and effective MTBFs, FMEAs, and more. The brand-new Electronic Parts Reliability Data (EPRD-2024) resource contains 1.2 million field failure rate data records of commercial and military electronic components and assemblies for use in reliability analyses.

Learn more and access EPRD-2024 through ROADS.

Failure Mode / Mechanism Distributions – FMD-2016

This databook contains field failure mode and mechanism distribution data on a variety of electrical, mechanical, and electromechanical parts and assemblies. This data can be used to assist in the performance of reliability analyses and assessments such as Failure Modes, Effects and Criticality Analysis (FMECA) and Fault Tree Analysis (FTA).

Reliability Online Automated Databook System (ROADS)

Reliability Online Automated Databook System (ROADS)

The Reliability Online Automated Databook System (ROADS) is a subscription that provides customized access to all the Quanterion Databooks: Nonelectronic Parts Reliability Data (NPRD), Electronic Parts Reliability Data (EPRD) and/or Failure Modes / Mechanisms Distribution (FMD).

Tools and Resources

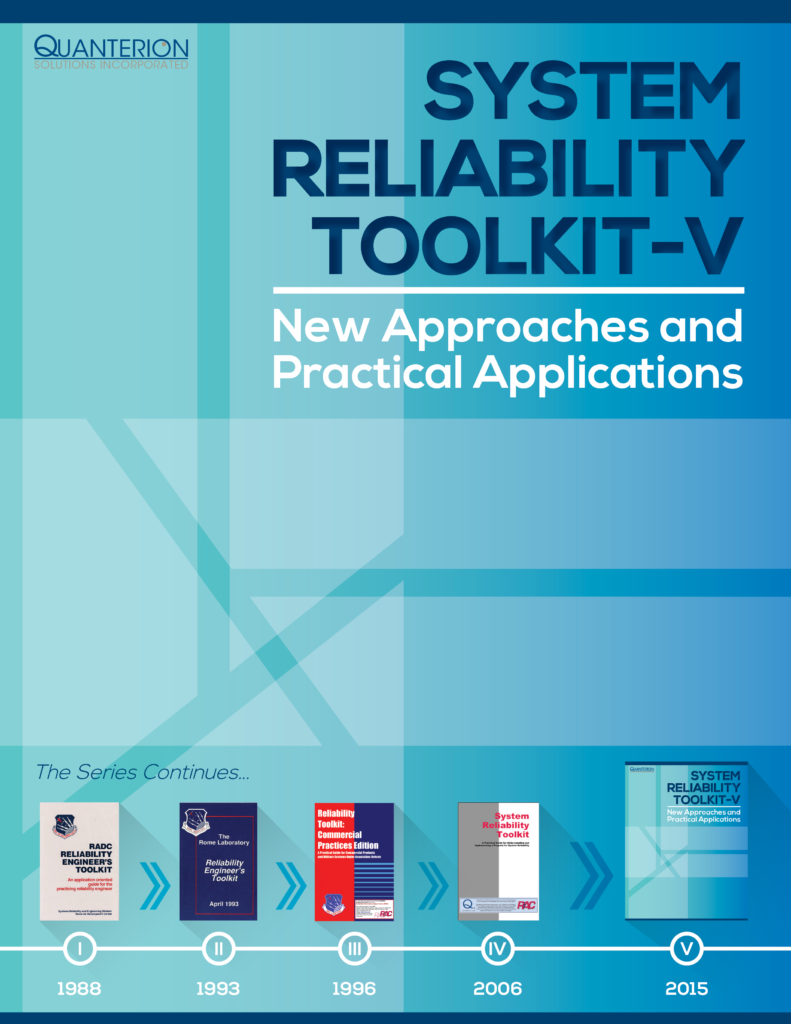

System Reliability Toolkit-V

This fifth toolkit in the popular series developed by Quanterion reflects the updated focus in RMQSI. Several of the same Quanterion staff members have been involved in all five titles in the series. Over 30 new topics have been added, and several others updated, with a minimum removal of topics from the “System Reliability Toolkit.” In addition, Appendices have been added stressing the practical application of the document’s practices throughout a program’s life.

Warranty Calculator

The Warranty Calculator planning and analysis tool provides automated calculations and comparisons for ten different warranty types in common use. The tool also includes data, information and references that provide further guidance for over 30 additional warranty types.

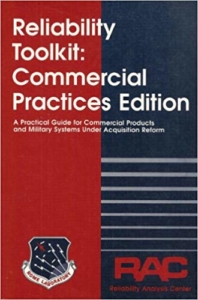

Reliability Toolkit: Commercial Practices Edition

Reliability Toolkit: Commercial Practices Edition

The “Reliability Toolkit: Commercial Practices Edition” helps both the commercial and military sectors deal with developing and manufacturing reliable products in today’s competitive markets. Over 80 topics, representing every aspect of a product’s reliability over its life cycle, have been well received by thousands of Toolkit users to date.

NOTE: The “Reliability Toolkit: Commercial Practices Edition” was published in 1995. It has been updated twice since publication with the latest version, “System Reliability Toolkit-V”.

Practical Applications of the RIAC System Reliability Toolkit

Practical Applications of the RIAC System Reliability Toolkit

The purpose of this publication is to provide illustrative examples of the more common mathematical calculations and statistical techniques utilized by reliability engineers in the practical performance of their daily activities. It is intended to be used as a companion to the RIAC “System Reliability Toolkit,” as the foundations of all of the techniques illustrated in this publication are discussed.

Reliability Modeling – The RIAC Guide to Reliability Prediction, Assessment and Estimation

Reliability Modeling – The RIAC Guide to Reliability Prediction, Assessment and Estimation

The purpose of this publication is to provide guidance on modeling techniques that can be used to quantify the reliability of a product or system. There are many ways in which this can be accomplished, depending on the product or system and the type of information that is available, or practical to obtain. It reviews the possible approaches, summarizes their advantages and disadvantages, and provides guidance on selecting a methodology based on the specific goals and constraints of the analyst.

Mechanical Analysis and Other Specialized Techniques for Enhancing Reliability (MASTER)

This document is specifically targeted to address the competing approaches to part reliability predictions, including statistical analysis of relevant failure data, physics of failure modeling, empirical failure models and data, and other less common but acceptable methods.

Weibull Analysis

The statistical analysis of an item’s failure data is widely regarded as one of the most accurate techniques for assessing its reliability in a specific application or environment. The Weibull distribution is especially useful because of its ability to characterize a wide range of potential data trends. More specifically, it can be fit to a dataset exhibiting an increasing, constant or decreasing failure rate, a unique feature that separates the Weibull distribution from its counterparts.

To learn more about reliability data collection and analysis, visit Quanterion’s associated reliability data collection and analysis informational page.

Stay up-to-date! Sign up for reliability engineering news and resources!

Find Quanterion Solutions on social media to access more reliability engineering information, resources, and more.