FMECA Resources for Any Engineer or Manager

Training

Reliability 201: Quantitative Reliability Analysis

Sign up for a related course: Reliability 201: Quantitative Reliability Analysis, to be hosted June 3-5, 2025 in Virginia Beach!

If you need to know the basics of quantitative reliability analyses as they apply to developing and fielding better products and systems, this course is for you. Design engineers, reliability engineers, and product/program managers will also benefit.

You will walk away from Reliability 201 with the ability to perform basic reliability analyses and interpret the results. Additionally, you will be able to apply a variety of analyses and techniques including Weibull Analysis, reliability growth models, stress-strength analysis, and others!

Learn more and register for Reliability 201: Quantitative Reliability Analysis!

Failure Mode, Effects and Criticality Analysis (FMECA) and Fault Tree Analysis (FTA)

FMECAs and FTAs are popular methods for determining the impact of failures on the product or system. This module focuses on these two popular approaches to system logic analysis. The discussion will begin with a discussion of the MIL-STD-1629 approach and then introduce the commercial IEC and SAE approaches to design FMECA’s. The FTA section focuses on the most popular basic symbols and high-level prioritization techniques. The topics include:

- Terms used in Failure Mode Effect Analysis

- Criticality Analysis

- Fault Tree Construction

- Quantitative and Qualitative Analysis

Access this FMECA/FTA online training video today.

FMECA Consulting

Could you use assistance in performing and interpreting an FMECA? Would you like to have an expert ensure that your reliability data is effectively collected, analyzed and used for informed decision making? Let Quanterion Solutions help! We have been providing customized reliability engineering consulting and analyses for decades.

Learn more about our custom reliability engineering consulting.

Failure Mode Data

Failure Mode/Mechanism Distributions (FMD-2016)

Failure Mode/Mechanism Distributions (FMD-2016)

The 2016 Edition of the Failure Mode/Mechanism Distributions (FMD-2016) contains field failure mode and mechanism distribution data on a variety of electrical, mechanical, and electromechanical parts and assemblies. This data can be used to apportion an item’s failure rate into modal elements and assist in the performance of reliability analyses and assessments such as Failure Modes, Effects and Criticality Analysis (FMECA) and Fault Tree Analysis (FTA). FMD-2016 contains over 990,000 new records, a 10-fold increase over the 98,000 records presented in its predecessor, FMD-2013. Access FMD-2016 through ROADS.

FMECA Publications

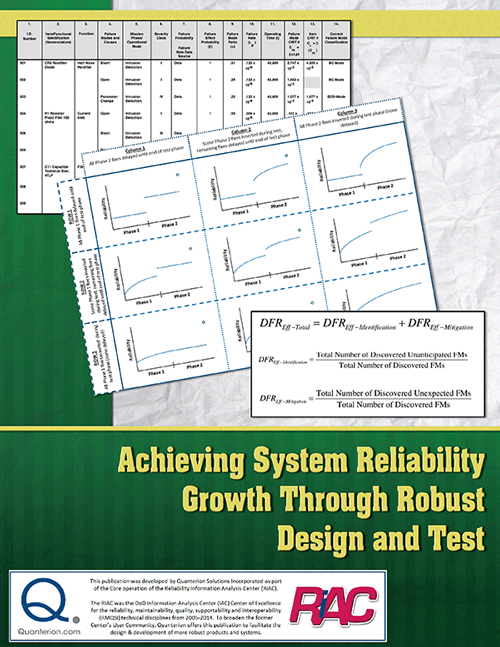

Achieving System Reliability Growth Through Robust Design and Test

Achieving System Reliability Growth Through Robust Design and Test

This book offers new definitions of how failures can be characterized, and how those new definitions can be used to develop metrics that will quantify how effective a Design for Reliability (DFR) process is in (1) identifying failure modes and (2) mitigating their root failure causes.

Learn more about this resource about achieving system reliability growth.

Expanded Applications of Software Failure Modes Effects Analysis – 2nd Edition

Expanded Applications of Software Failure Modes Effects Analysis – 2nd Edition

This book expands the discussion of FMECA beyond the realm of the MIL-STD-1629A hardware approach. Commonly-used commercial standards (SAE J1739 and IEC 60812) are introduced. Hardware and Software FMECA (DFMEA), Process FMECA (PFMEA) and Human Systems Integration (HSI)-based PFMECA methods are discussed, with particular attention given to the process, required information, expected results and analysis alternatives. The concept of an Integrated FMECA (I-FMECA) is also introduced.

Buy Expanded Applications of Software Failure Modes Effects Analysis today.

Expanded Applications of FMECA

Expanded Applications of FMECA

This book expands the discussion of FMECA beyond the realm of the MIL-STD-1629A hardware approach. Commonly-used commercial standards (SAE J1739 and IEC 60812) are introduced. Hardware and Software FMECA (DFMEA), Process FMECA (PFMEA) and Human Systems Integration (HSI)-based PFMECA methods are discussed, with particular attention given to the process, required information, expected results and analysis alternatives. The concept of an Integrated FMECA (I-FMECA) is also introduced. Learn more and buy Expanded Applications of FMECA today.

Failure Modes and Effects Analysis (FMEA) / Failure Modes, Effects and Criticality Analysis (FMECA)

Failure Modes and Effects Analysis (FMEA) / Failure Modes, Effects and Criticality Analysis (FMECA)

There are very few reliability design analysis tools that are as widely practiced as Failure Modes and Effects Analysis (FMEA) or its derivative, the Failure Modes, Effects and Criticality Analysis (FMECA). The FMEA/FMECA is a tool by which a design is analyzed to identify all credible potential ways that the building blocks of a design can fail, and the impact that these failures can have on the product or system. The process begins by identifying the building blocks (for example, individual components or functional blocks), then enumerating the functional requirements for each block, and finally listing the effect(s) of failure on both the local and higher-level assemblies until the impacts on the final product or system are projected. For this reason, the analysis is referred to as a “bottom-up” approach.

Order the FMEA/FMECA resource today.

Reliability Modeling – The RIAC Guide to Reliability Prediction, Assessment and Estimation

The purpose of this publication is to provide guidance on modeling techniques that can be used to quantify the reliability of a product or system. There are many ways in which this can be accomplished, depending on the product or system and the type of information that is available, or practical to obtain. It reviews the possible approaches, summarizes their advantages and disadvantages, and provides guidance on selecting a methodology based on the specific goals and constraints of the analyst.

Learn more about this reliability modeling resource.

System Reliability Toolkit-V

This fifth toolkit in the popular series developed by Quanterion reflects the updated focus in RMQSI. Several of the same Quanterion staff members have been involved in all five titles in the series. Over 30 new topics have been added, and several others updated, with a minimum removal of topics from the “System Reliability Toolkit.” In addition, Appendices have been added stressing the practical application of the document’s practices throughout a program’s life.

Learn more and order the System Reliability Toolkit-V.

Reliability Toolkit: Commercial Practices Edition

Reliability Toolkit: Commercial Practices Edition

The “Reliability Toolkit: Commercial Practices Edition” helps both the commercial and military sectors deal with developing and manufacturing reliable products in today’s competitive markets. Over 80 topics, representing every aspect of a product’s reliability over its life cycle, have been well received by thousands of Toolkit users to date.

Learn more about this legacy version of the popular Reliability Toolkit.

NOTE: The “Reliability Toolkit: Commercial Practices Edition” was published in 1995. It has been updated twice since publication with the latest version, “System Reliability Toolkit-V” (listed above).

QuART ER (Enhancing Reliability)

QuART ER (Enhancing Reliability)

This 2011 release features over 2 dozen new or improved tools over QuART PRO. QuART ER updates more than 10 tools and adds more than 15 new tools to the tool set available in QuART PRO, including the “Ask a Quanterion Expert” function that allows users to direct their reliability questions to an ASQ certified reliability expert at Quanterion.

Access this versatile reliability resource software today.

To learn more, visit Quanterion’s associated Failure Modes Effects, Effects and Criticality Analysis (FMECA) page.

Stay up-to-date! Sign up for reliability engineering news and resources!

Follow Quanterion Solutions Incorporated on social media to access more reliability engineering information, resources, and more.